Responsibly and Reliably Powering New York

Cricket Valley Energy Center (CVEC) supports a sustainable energy future powered by cleaner electricity. The facility uses efficient combined-cycle natural gas turbine (CCGT) technology which minimizes emissions and provides a steady source of cleaner electricity to enable the further build-out of renewables in New York. Reliance on CVEC’s cleaner electricity can diminish continuing dependence on New York’s dual-fuel peaking units, many of which have been in operation for more than 50 years and produce far greater emissions.

Furthermore, New York Independent System Operator (NYISO) estimates that the installed capacity in New York will need to triple from the current 37 GW to between 100 GW and 130 GW by 2040 to accommodate the electric load growth projected due to electrification, and state-of-the-art data centers, and microchip manufacturing. The CVEC facility’s approximately 1,100 MW of cleaner energy capacity provides power to support the region’s forecast load growth.

CVEC’s Title V Air Pollution Control Permit is currently up for renewal to ensure the facility’s continuing compliance with state and federal air quality standards.

The U.S. now produces nearly all the natural gas it uses, making it a key domestic resource of cleaner energy generation.

As New York increasingly relies on renewable energy for its power supply, ensuring a steady and dependable energy source is more important than ever. Electricity produced by natural gas can be dependable year-round, when variable energy resources like wind and solar and wind may not be. Power generated through CVEC also produces fewer emissions than other aging power facilities that are still operating in New York.

How does Cricket Valley Energy Center work?

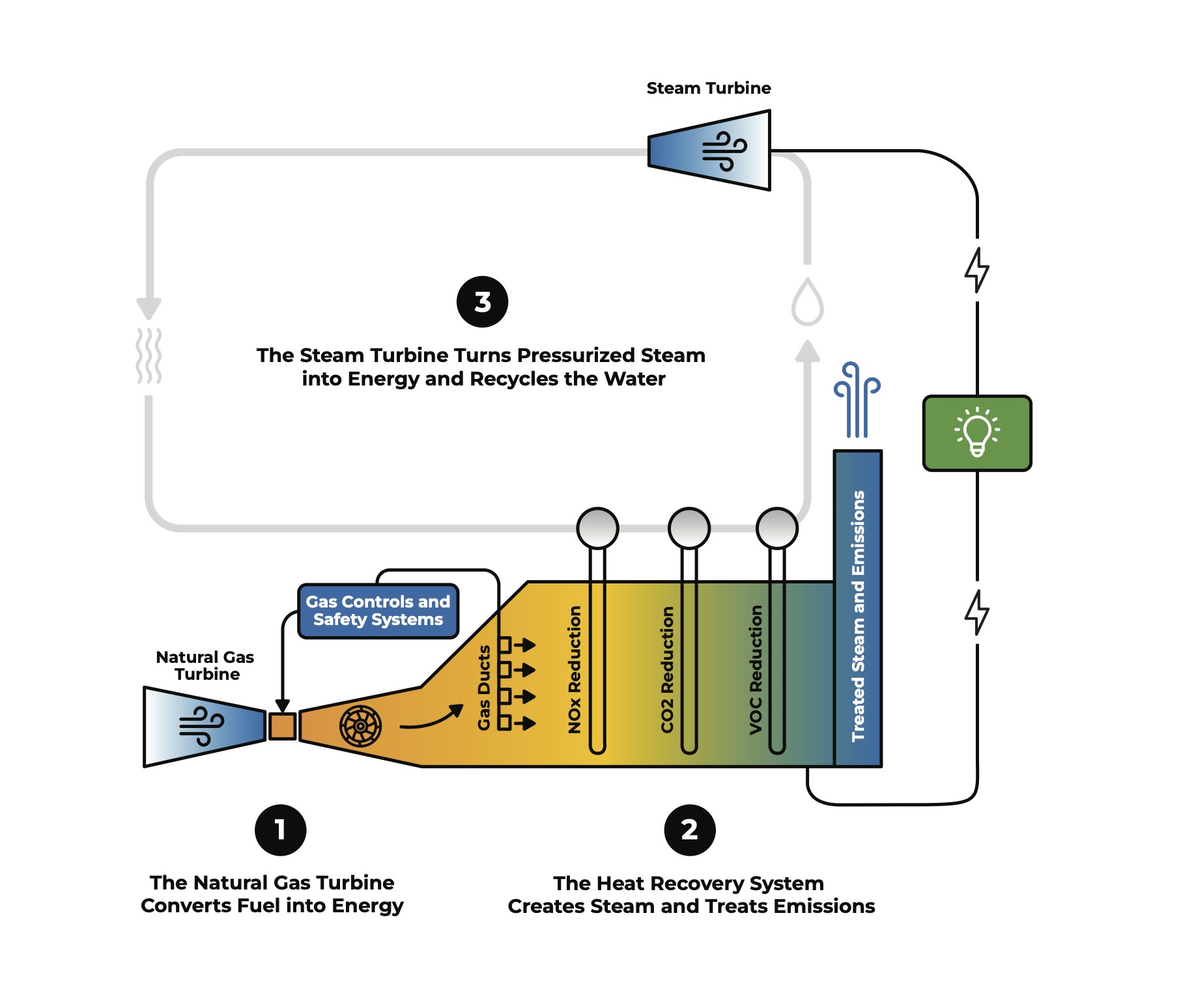

Combined-cycle natural gas facilities like CVEC are highly efficient power facilities that use two types of turbines to produce electricity: gas and steam.

Step 1: The Natural Gas Turbine Converts Fuel into Energy

Air is compressed and mixed with natural gas, which is then heated to a very high temperature. The hot air-fuel mixture moves through the gas turbine blades, causing them to spin. This spinning drives a generator that converts some of the kinetic energy into electricity.

Step 2: A Heat Recovery System Creates Steam and Treats Emissions

The exhaust heat from the gas turbine, which would otherwise be wasted, is captured by a heat recovery steam generator (HRSG). The HRSG uses this heat to create steam, which is delivered to the steam turbine.

Step 3: The Steam Turbine Turns Pressurized Steam into Energy and Recycles the Water

The steam turbine uses the steam’s energy to spin and drive a generator shaft, producing additional electricity. This process can produce up to 50% more electricity from the same fuel than a traditional simple-cycle facility, making it a more efficient and environmentally friendly option for power generation.

Steam and exhaust, created as a byproduct, travel back through the HRSG to be treated for chemical compounds at federal and state regulated levels. After chemical compound levels are treated, measured, and approved, the treated steam and emissions are then discharged through the stack.