Ask Cricket Valley

Click on a topic to learn more and link to related pages. Contact us for more information.

Air Quality

Cricket Valley Energy Center (CVEC) is using the state-of-the-art technologies to ensure that the facility produces the lowest emissions rates of any natural gas powered combined cycle plant in New York State. CVEC’s impact on air quality has been deemed insignificant even for the most vulnerable individuals, including those with asthma and the elderly.

As one of the most efficient, reliable and least emitting energy producers, CVEC will provide electricity that currently is produced by higher polluting oil, gas, and coal fired power plants identified on the map below, enabling New York State to displace some of those other producers, and helping reduce regional emissions of NOx, SO2 and CO2.

By design, the emissions from CVEC will be released at sufficient height to dissipate emissions.

Water Quality

Air-cooling technology at Cricket Valley Energy Center (CVEC) reduces water use by more than 98%, and a rooftop rainfall capture system is used to provide a supplemental supply of water and a stormwater management plan. On average, the facility uses about 15 gallons of water per minute during cooler months and up to 60 gallons per minute during the hotter summer months. By way of comparison, a garden hose uses 5 to 10 gallons per minute.

No process water is discharged into the Swamp River and CVEC has incorporated stormwater management techniques to minimize impact on the flow of the River. Wells drilled on the CVEC site into the bedrock aquifer produce sufficient water to meet the needs of the facility and have been tested to ensure that impacts to neighboring wells, the surface aquifer, the Swamp River and associated wetlands are insignificant.

Studies conducted by Russell Urban-Mead, Senior Hydrogeologist and author of the 1999 Harlem Valley Aquifer Study, found that even during drought conditions CVEC will have a small impact on the water budget, with sufficient water available for future projects in the area.

Sight, Sound & Smell

Sight

A 300-foot buffer of existing mature trees along Route 22 and the location of the plant in a valley reduces the visual impact of the site. In addition, CVEC co-located the three facility stacks to preserve the rural character of Dover.

Sound

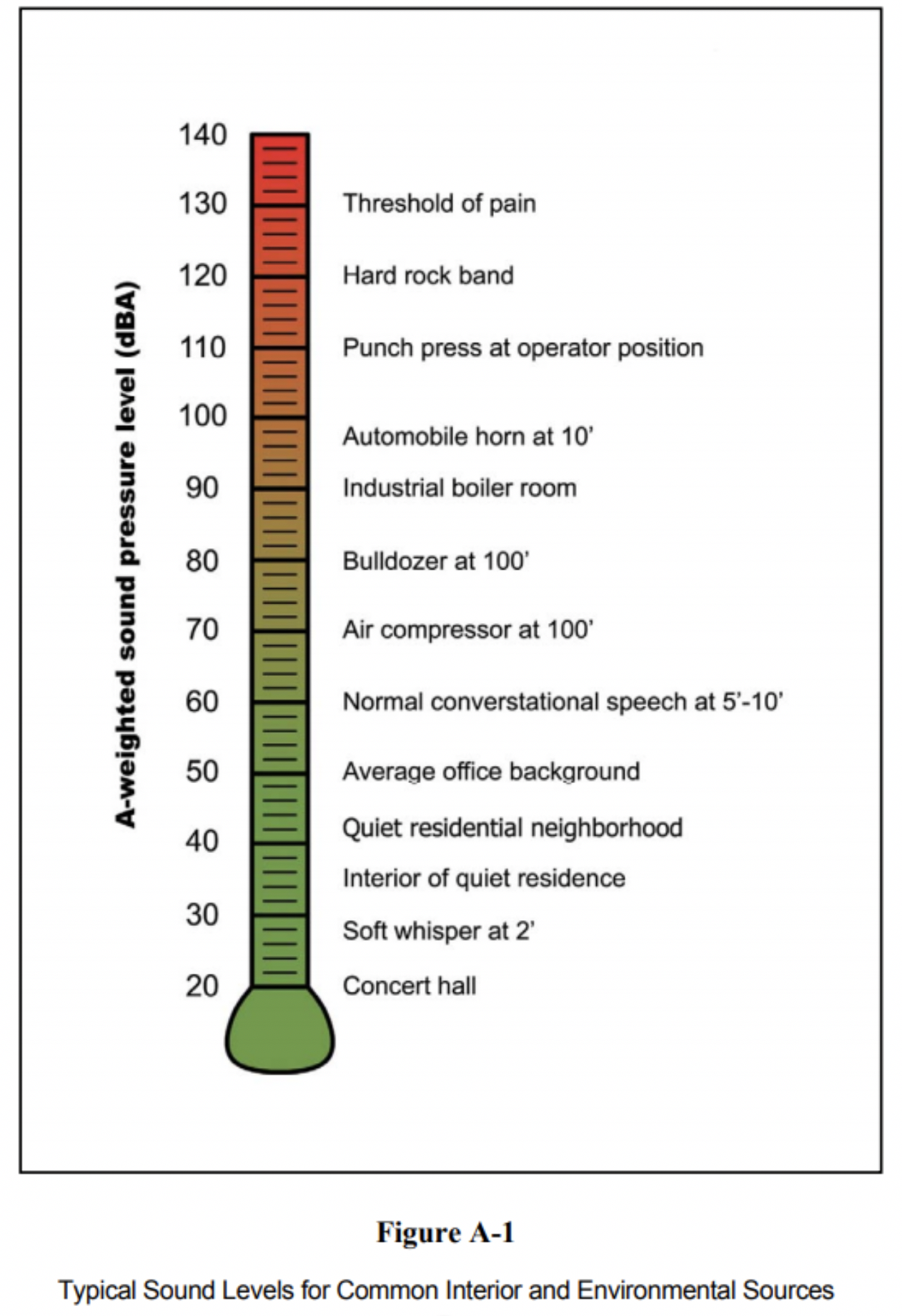

During the environmental review and permitting process, CVEC completed noise level studies to ensure the plant would be at or below 50 decibels, the requirements of the DEC and the Dover Town Zoning Code. The 50-decibel level is comparable to the background noise of a typical office and sounds like a faint hum. Sound levels of 50-dB(A) will be met at all non-industrial property lines.

During the environmental review and permitting process, CVEC completed noise level studies to ensure the plant would be at or below 50 decibels, the requirements of the DEC and the Dover Town Zoning Code. The 50-decibel level is comparable to the background noise of a typical office and sounds like a faint hum. Sound levels of 50-dB(A) will be met at all non-industrial property lines.

A decibel, or dB(A), is a degree of loudness: typical sound levels are shown in Figure 1.

Prior to the project starting construction, CVEC worked with the Town of Dover to finalize a noise mitigation plan which demonstrates how the site’s operations will be consistent with the Town of Dover Noise Code and other related State Environmental Quality Review Act (SEQRA) requirements. This plan was reviewed and approved by the Town of Dover. During operations, CVEC complies with the Town Noise Ordinance at property boundaries, specifically 50-decibel at the property boundary and 65-decibel along the Metro North Rail.

The CVEC site was chosen, in part, for the wide tree buffer that provides a visual and sound barrier. In addition, the plant has been designed to enclose most of the equipment within an insulated and soundproof building structure, which helps mitigate noise levels.

Smell

There are no odors associated with the routine operations of natural gas-fueled power plants.

Wetlands & Environment

There is no work done within the Great Swamp Critical Environmental Area, and no hydraulic fracturing, or “fracking,” at this project.

Seventy-nine (79) of the project’s 193 acres have been conserved, and the compact design reused the existing industrial footprint to limit the project area. A wetland area that was damaged by previous uses has also been restored by CVEC and conforms to the federal “no net loss” wetland policy.

No significant wildlife habitat areas have been lost, and no rare, threatened or endangered species have been displaced.

The project was recognized with the Ducks Unlimited Wetlands Remediation Award in 2017 for revitalizing and conserving the site’s 79 acres of wetlands, and its commitment to protecting and preserving the wetlands for future generations. Once an abandoned industrial site, CVEC restored wetlands damaged during prior uses of the property, and purchased and remediated an adjacent property, locally known as the Rasco site.

Traffic & Safety

A traffic study of the cumulative impacts of this project, additional projects (including Dover Knolls) and population growth in Dover, demonstrated that all intersections operate at an acceptable level of service. These findings are discussed in detail in Section 6.2 of the FEIS, available in the Archive section of this website.

CVEC’s Comprehensive Site and Safety Plan (CSSP), developed in cooperation with local Dover fire and emergency officials, details safety procedures, training and, a zero-tolerance policy for non-compliance.

Unannounced safety review visits are conducted by regulating agencies, perimeter fencing and electronically monitored gates are installed, and authorized staff is on site 24 hours per day, 7 days per week, 365 days per year.

CVEC coordinates safety planning with the Town of Dover’s first responders and Dutchess County officials, along with NYSDOT and OSHA.

Use and Storage of Aqueous Ammonia

Plants like CVEC commonly use two types of ammonia in operation: anhydrous and aqueous. Anhydrous is much less expensive, but aqueous ammonia, a solution of water and ammonia, is safer to transport, store and handle. When the plant begins operations, CVEC will use aqueous ammonia.

Jobs & Taxes

The project provides the productive reuse of an inactive industrial parcel, meets regional energy needs, and contributes to the tax base without significant impact to the community or environment.

During the construction of the facility, over 1,100 workers were employed, representing over $80 million in annual salaries.

During operations, the direct, indirect and induced employment impacts of up to 28 permanent jobs contribute approximately $3.4 million in labor income to Dutchess County.

In addition to job creation, the local economy benefits from the purchase of locally sourced materials and services. The annual operation of the project results in an estimated increase in regional economic activity of $21.8 million.